02.

Operation ManagEMENT

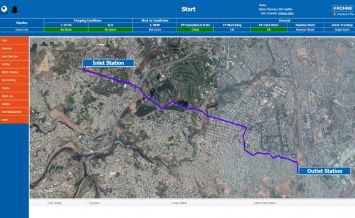

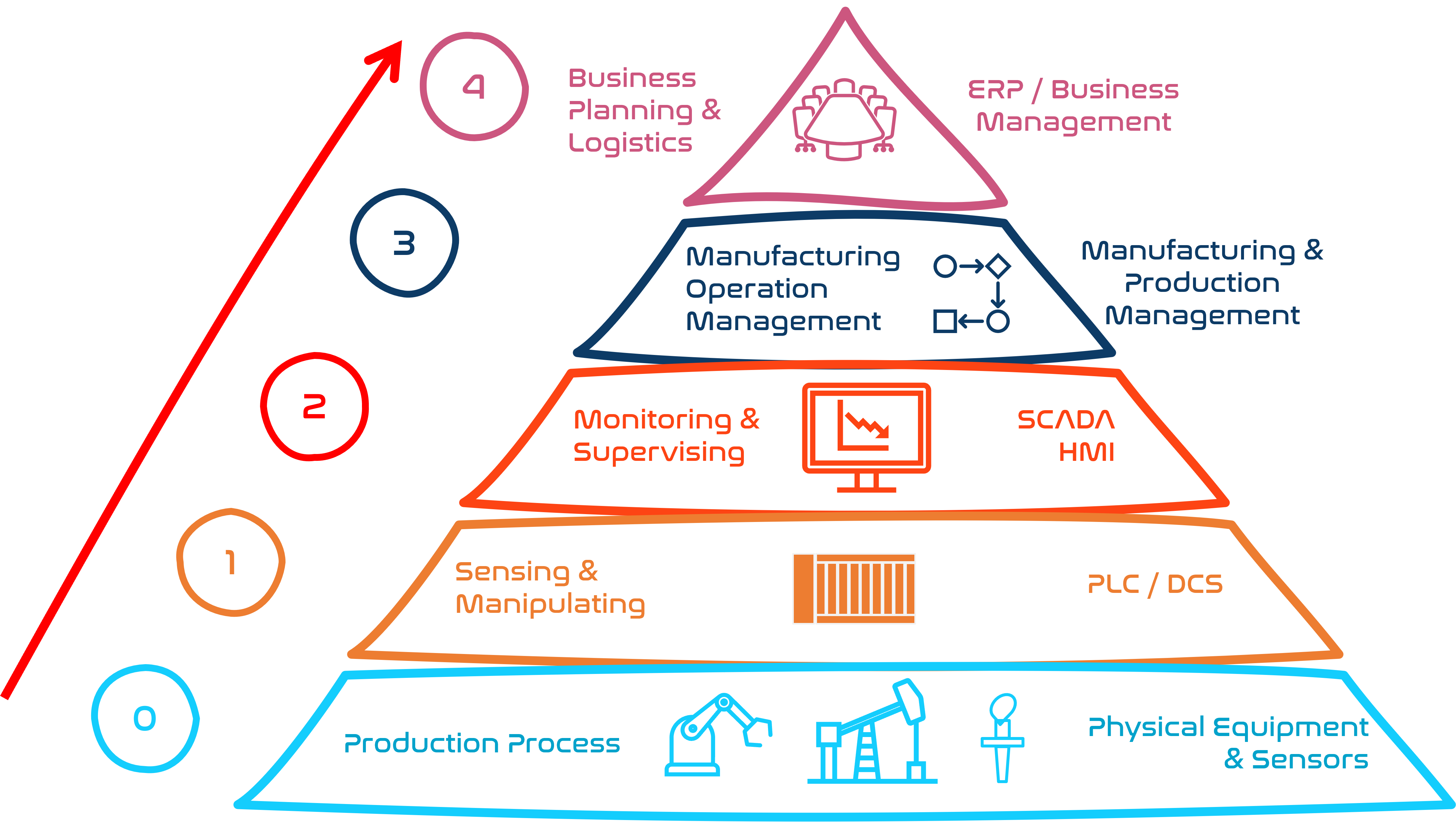

Many plants still have few manual manufacturing processes meanwhile the fully automated factories might lack a single master platform integrating the isolated systems. Different SCADA options are available for full customization to suit the requirements of each facility.

Edge & HMI SCADA

Economic yet powerful SCADA for machine or unit automation with rich UI that can adapt to any production process or recipe with rich reporting mechanisms.

Master SCADA

Enterprise SCADA for managing hundreds of thousands of tags, with extensive integration adapters for any other PLC, DCS or SCADA. Multi-layer / multi-site installation with full redundancy is possible.

03.

Information Management

In typical industrial organiztions, operation data is scattered in multiple systems (PLC, DCS, SCADA, excel sheets). Correlation and analysis of operation data with corporate and business data is done manually. Automatic consolidation, analysis, reports generation, and smart dashboards are needed to have up-to-date holistic view of the organization performance.

AVEVA Historian

AVEVA PI System

04.

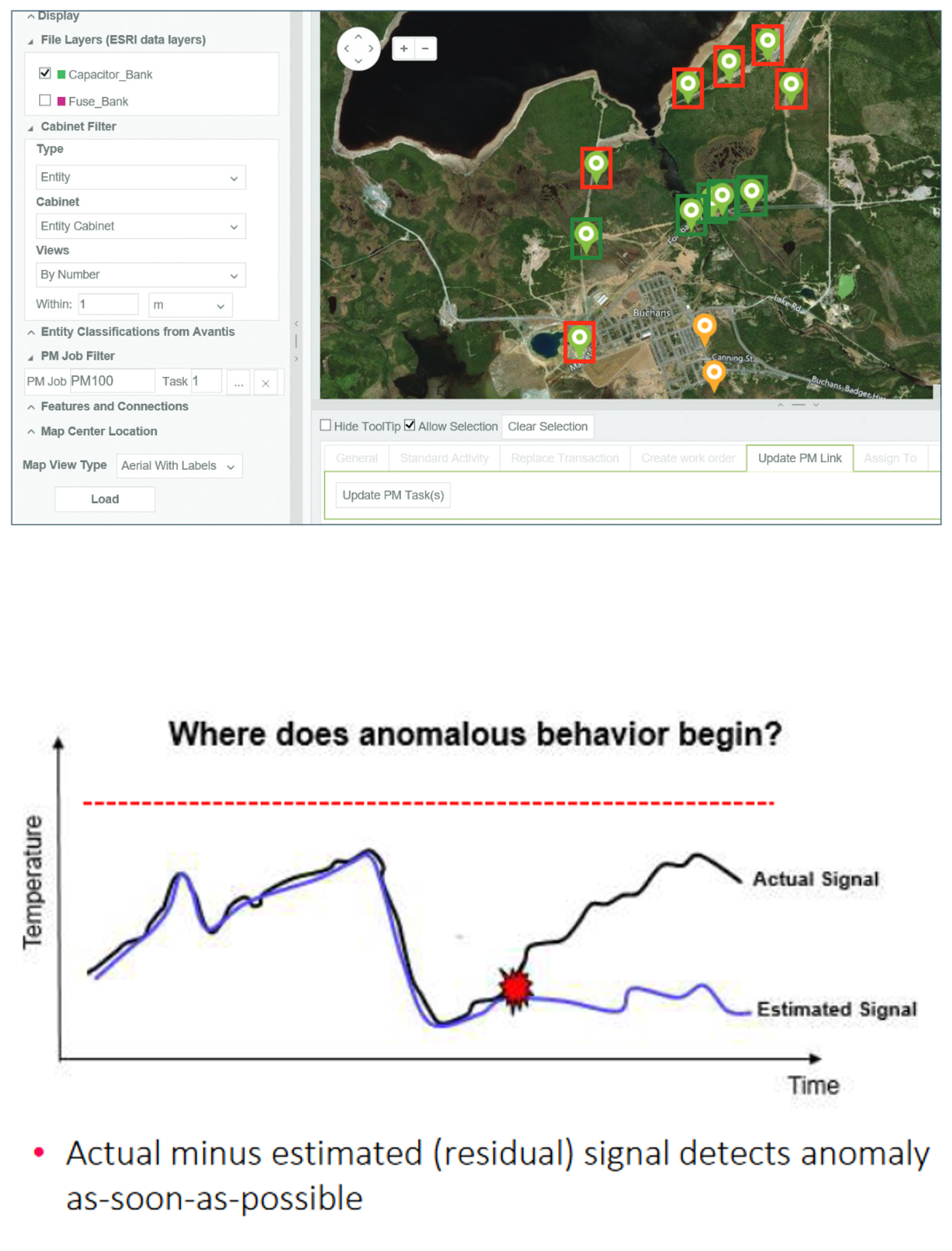

Asset Management

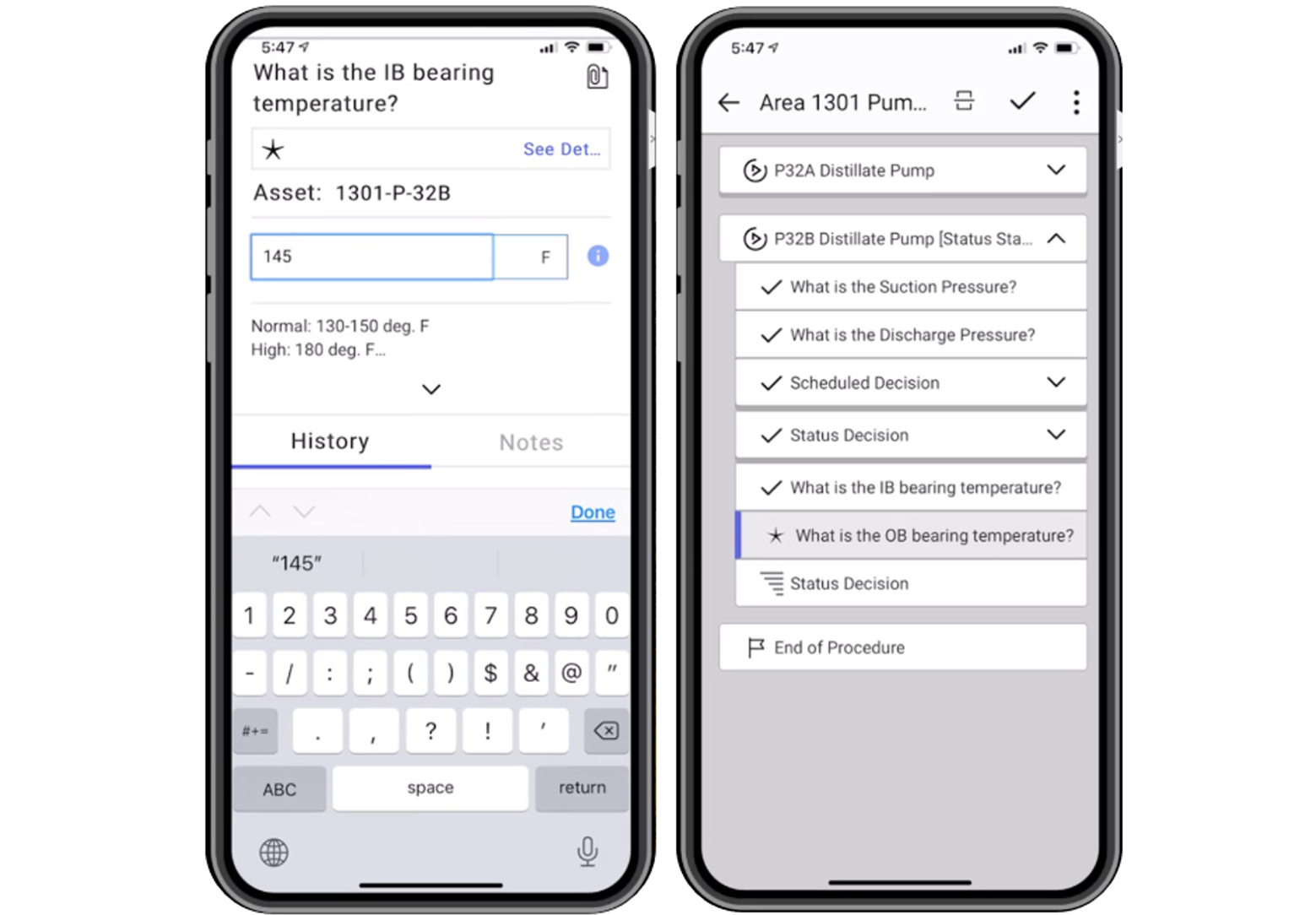

Factories and plants mandate that assets are utilized to their maximum overall efficiency (OEE), smartly maintained with lowest cost possible and their lifecycle is completely digitalized and seamlessly managed from procurement until their retirement.

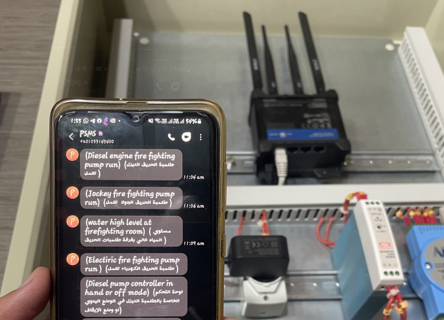

Enterprise Asset Management (EAM)

Managing the lifecycle of plant assets is crucial, starting from its vendor data to its maintenance schedule up to spare parts procurement. Our partner vendor EAM system, programmed and customized by AutomatiX, will provide a 360º view and management of all asset's static & operational data and its OEE.

Condition Monitoring & Predictive Maintenance

Through condition monitoring, like our solution AssetCare®, you can monitor all asset parameters, whether temperature, pressure, vibration, etc. Additionally, advanced AI solution can predict future failures and appropriate corrective actions can be prescribed.

Want to see one of the solutions in action?